Safer Workplaces with Advanced Screwdriver Tools

Providing a healthy work environment, and ensuring the well-being of employees is a crucial element for all organizations. Companies that are engaged in production or assembly activities today, are aware more than ever how important aspect worker safety is. In our present times, analyzing activities at the workplace, using advanced risk-mitigation tactics, and a ‘safety above all things’ - mentality is contributing to an overall decline in workplace injuries, and fatalities across the board in many industries. Developing countries are also starting to introduce new regulatory and legislative measures for safer workplaces.

Even though the rate of injuries at the workplaces is declining on average, there are still cases when employee safety cannot be guaranteed, due to the misuse of tools. Each different tool in assembly serves a specific purpose. According to the National Safety Council, however, screwdrivers are probably the most misused tools in the workplace. Misuse of the tool can create deviations on it, which can lead to an increased risk of injury when the tool is used for its purpose. Additionally to higher safety standards, and increased vigilance on the assembly lines, assets, such as innovative, robotic screwdriver tools are able to increase the safety of the workplace greatly.

Here are some of the benefits that these solutions can offer to create better, and safer workplaces:

- Collaborative work environment

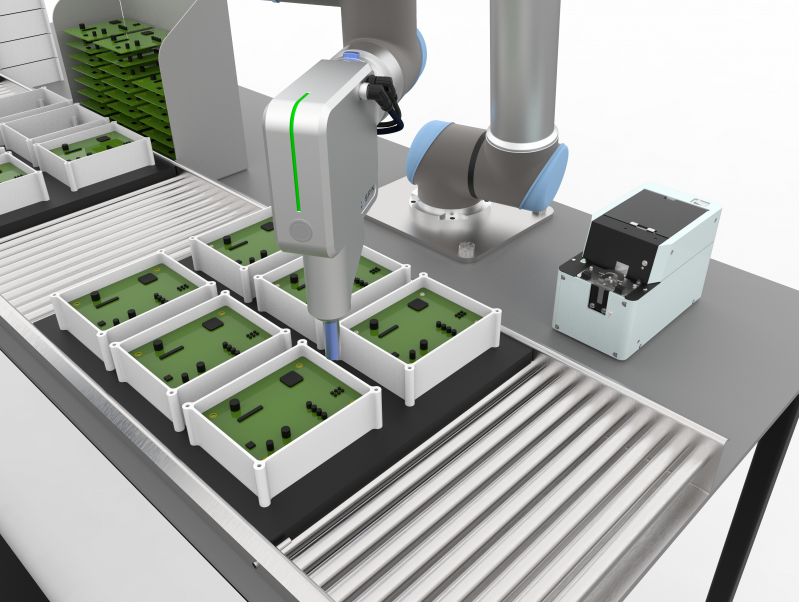

Screwdriver tools that are designed to be used by cobots (collaborative robots) can ensure that screwing tasks can be automated in a safe way, without having to use up significant space on the shop floors, or create robot-only areas within the workplace. Cobots can maximize productivity while also being able to work together with employees safely. With the ability of robot and human collaboration, screwdriver and assembly tasks, in general, are becoming more flexible, precise, and efficient.

- Additional protection through design

Some robotic screwdriver solutions, such as the Plug ‘n’ Produce Screwdriving Tool comes with a safety shield, which covers the rotating elements, making sure the human operators are provided with added safety on the job. In case the screwdriver collides with any object, the built-in safety sensor immediately stops the cobot.

- Reduction in the misuse of tools

Even though many workplace injuries happen by accident, a great number of these cases are due to the misuse of the tools used for the improper task. By delegating tasks on the assembly lines to robots and cobots, many of these processes can be implemented safely without the misuse of the tools, reducing the possibility for injury, and downtimes.

The automation of tasks on the assembly lines was traditionally provided by human operators. The increase in the rate of automation, and the easier access to better assets, such as advanced screwdriver tooling for robots/cobots allows manufacturers to create safer workplaces, and reduce the risk of injury on the job significantly.

Learn more about our screwdriver tooling, and find out what other benefits it can provide for companies.