5 Reasons to Use Cobots for Screwdriving Applications

Manual screwdrivers used to be the go-to solutions in assembly through many industrial applications. Their importance, however, is becoming less and less significant as automation creeps into almost all the areas of manufacturing.

Using only manual screwdrivers can result in variable output quality, unpredictable cycle times, absenteeism, and less stable production in general.

Traditional automated screwdriver solutions can offer much better productivity, can reduce cycle times, increase the quality, and move employees from the assembly lines to more value-producing activities.

However, highly specific, automated screwdriver systems are usually quite expensive, require complex programming for initial setup, changeovers take a long time, and error-proofing can be problematic as well.

Due to the higher costs, and the specificity of these assets, traditional automation in assembly is generally more beneficial for large production volumes and is more accessible to big enterprises.

The Power of Cobot-Enhanced Screwdriving Solutions

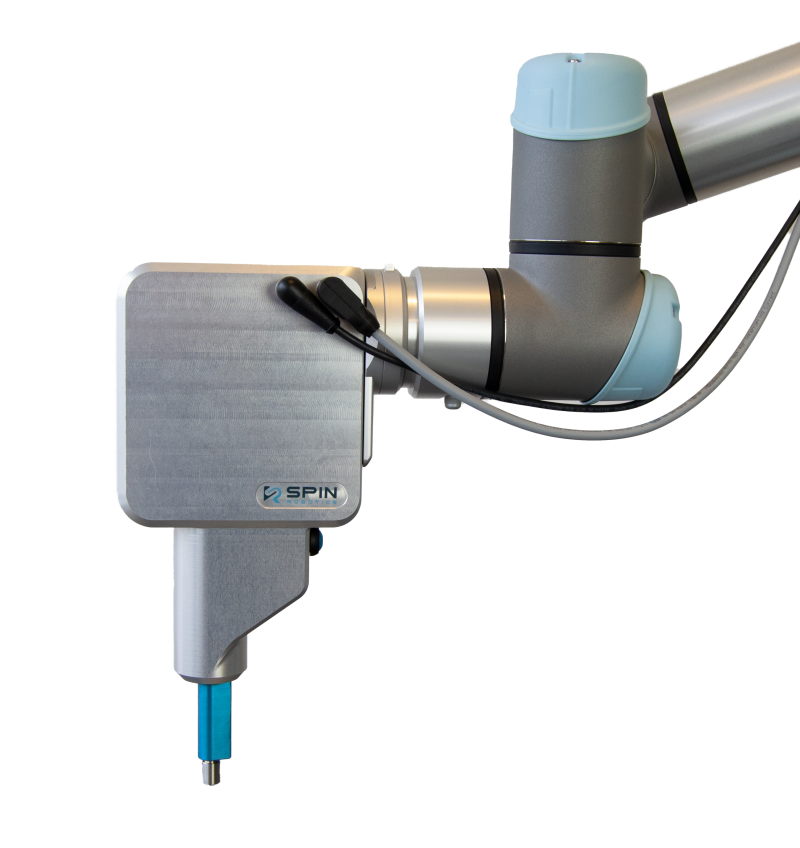

Collaborative Robots (Cobots) are designed to work safely alongside human employees while enhancing productivity, and quality by removing workers from strenuous, hazardous, and monotonous physical tasks, such as the assembly of various workpieces.

Today, robots and cobots are less expensive than in the past, due to the maturation of these technologies, and are more readily accessible to smaller manufacturers as well.

Robotic screwdriver systems that are designed to be used by cobots are ideal for flexible production, assembly applications that require high torque, multiple fasteners, and quick changeovers.

1. Simple setup and configuration process

Easy setup and configuration are a major benefit of these systems, which allows companies to save time, and expenses from complex setup processes.

2. Return on investment

Investing in an intelligent screwdriver solution that can be used by cobots, allows companies to lower their prices and beat competitors in the market, in a short time as 10-12 months.

3. Work environment safety

Companies and employees alike are often concerned about safety questions when people are working around automated devices and operating in hazardous tasks. This reaction is based on experiences using older, non-collaborative technologies, and a general reluctance from adopting new solutions.

However, in the case of cobots, advanced motion sensors, and software settings that prioritize worker safety above all ensures, that no harm will be caused to employees by these robotic assets.

4. Shorter assembly and changeover times

Time is one of the most critical aspects of manufacturing and assembly. The time needed for assembly and changeovers can be reduced by more than 40-60%, with the use of intelligent screwdriver solutions and cobots.

5. Data-supported quality monitoring

With the integration of advanced data tracking and analytics tools, quality assurance is much easier than it used to be in the past.

The online quality assessment allows manufacturers to look into the data about the torque values of each individual screw or detect insertion failures before the specific item leaves the assembly line. This greatly reduces the chance of quality issues, and downtimes.

To learn more about our Intelligent Plug’n’Produce Screwdriving Tool, visit our website, or contact us directly for more information.