SD-Series

The truly safe collaborative screwdriving solution. Start automating your screwdriving assembly today, with the Spin Robotics SD-Series.

- True collaborative safe

- Consistent screwdriving

- High torque accuracy

- Automatic bit-change

- Tighten screws between 0.2-12Nm

- High Flexibility

Get a Quote

Download Product Sheet

Meet All-in-one Screwdriving Solution for your production

.

Truly Collaborative

•

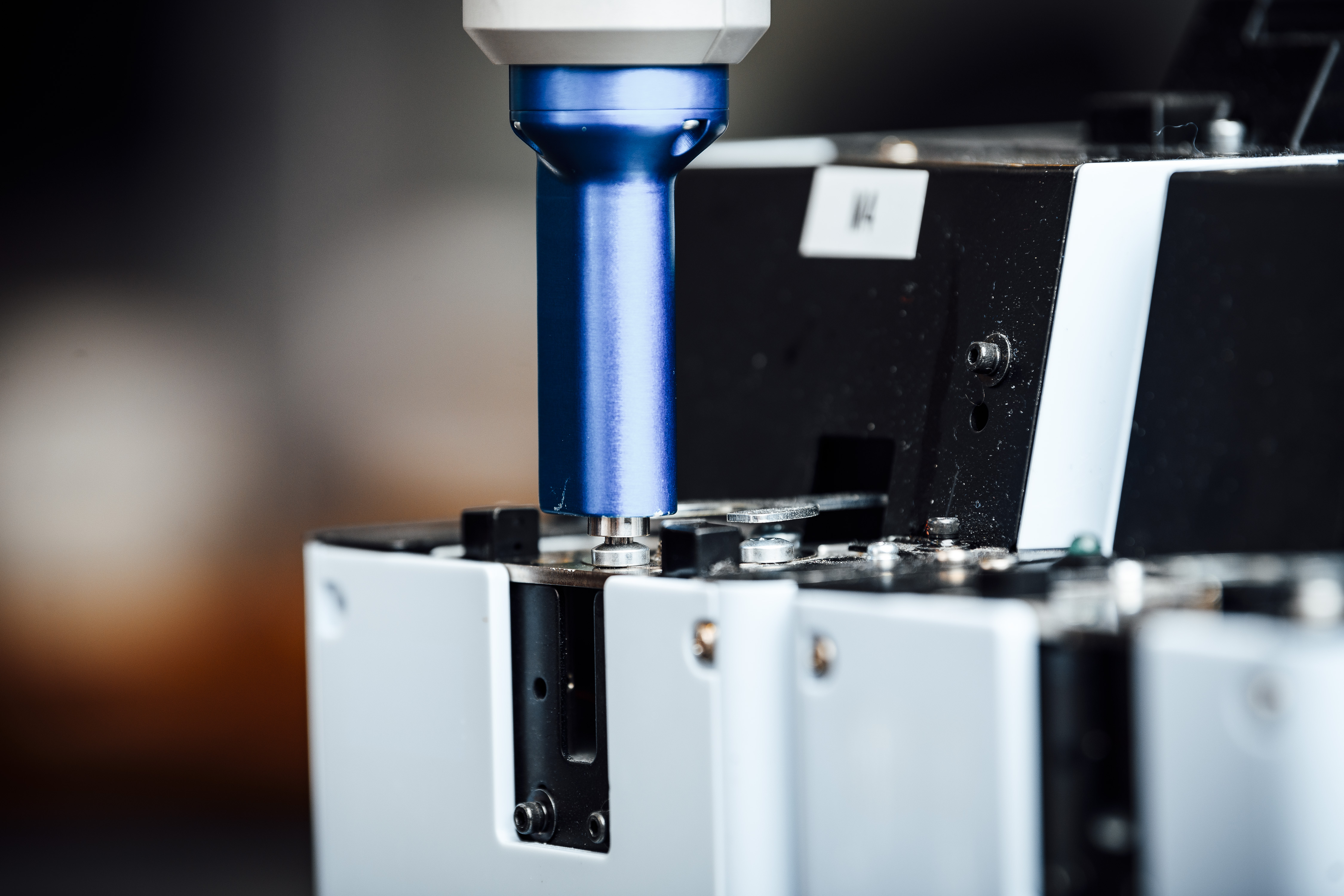

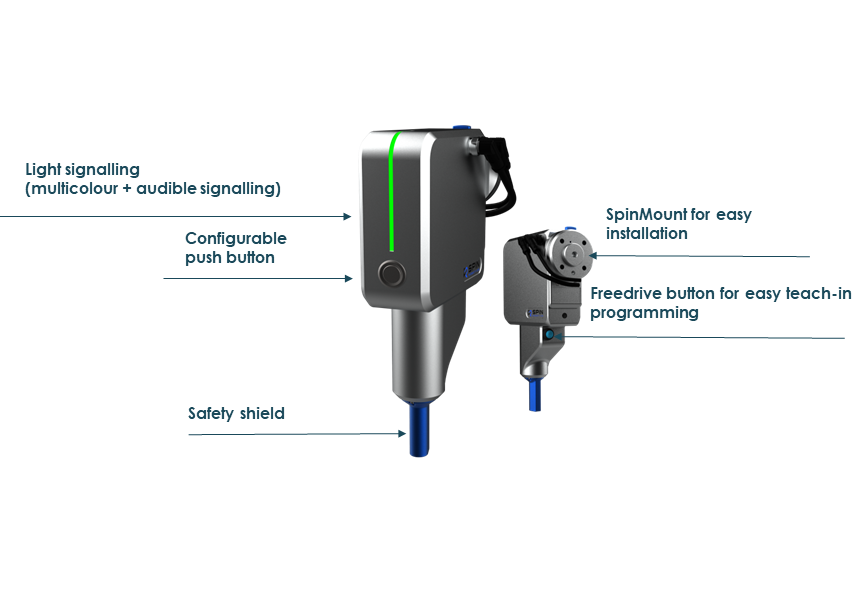

The Spin Robotics SD-Series has a high level of safety. The blue safety shield covers the screw. The spring-loaded slide on the back is a last resort. When the spring goes up, a sensor stops the robot but lets you lift the tool away.Easy Hand-guided Programming

•

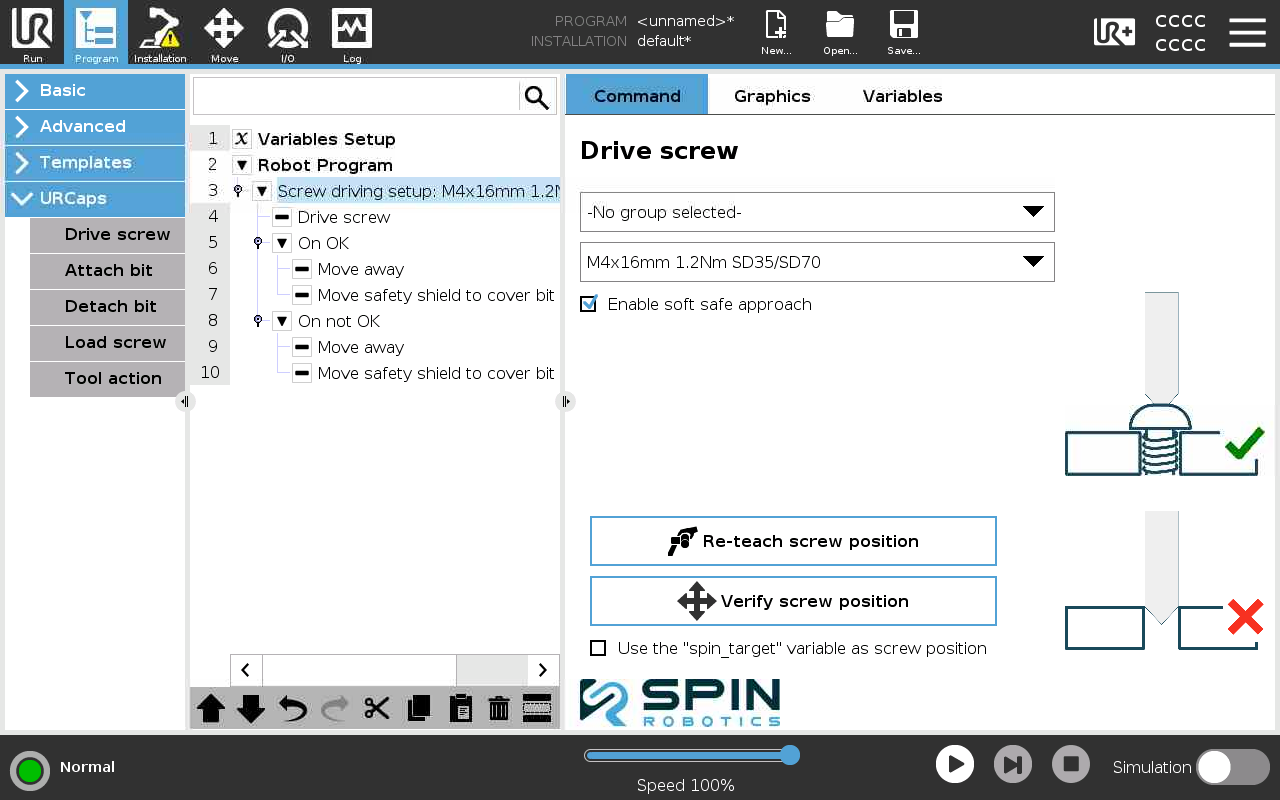

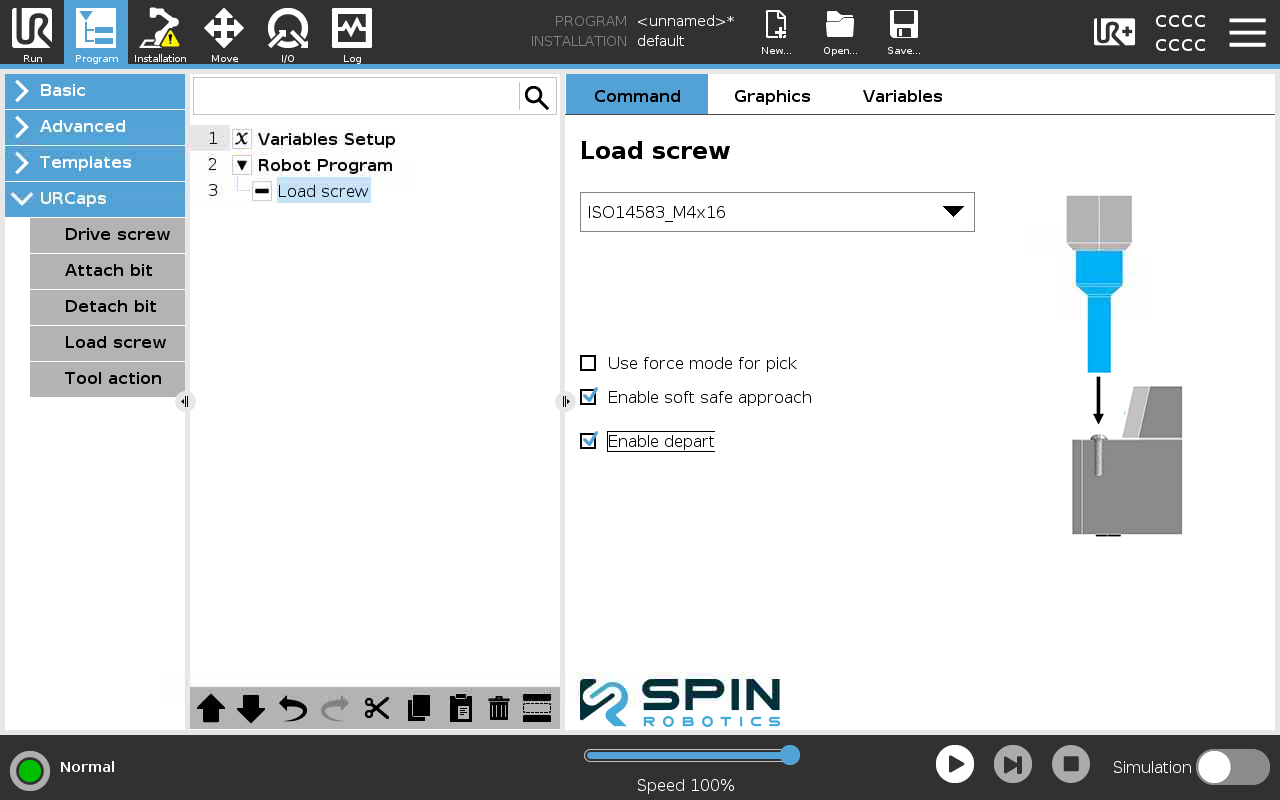

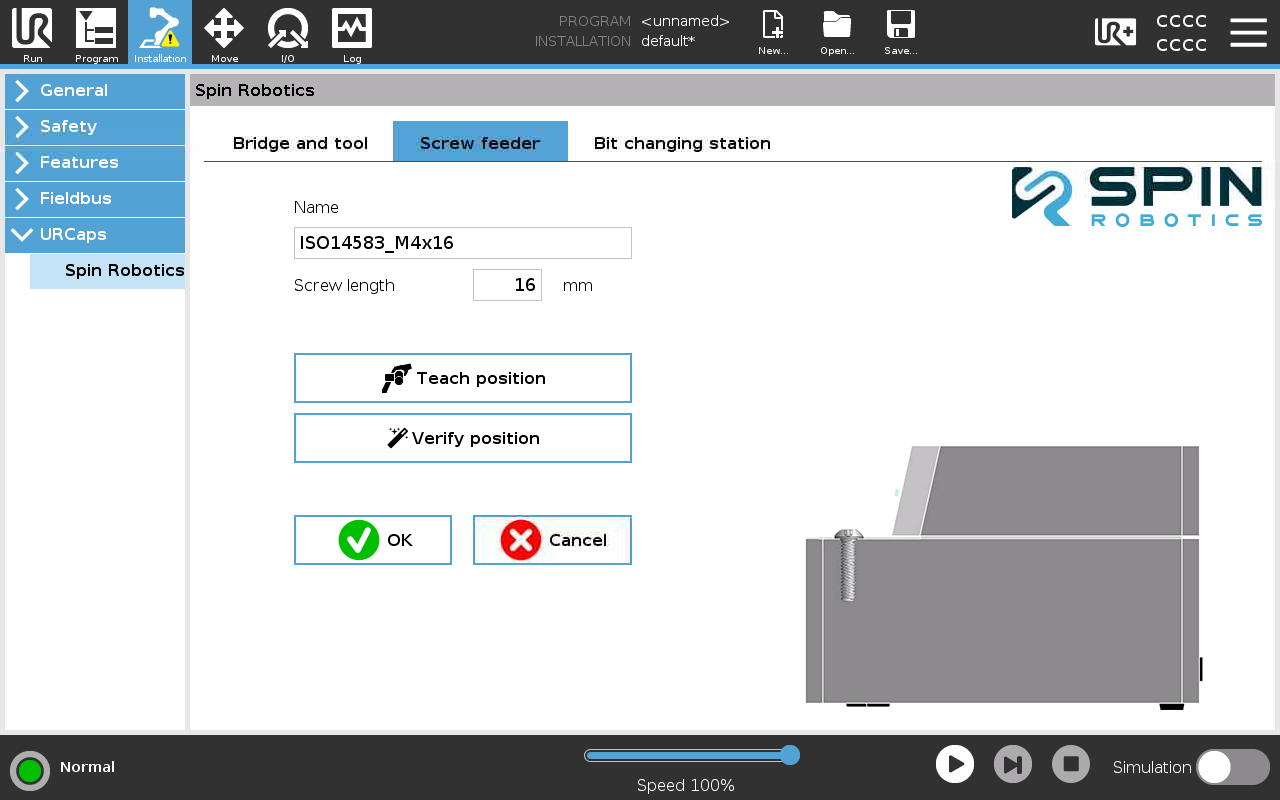

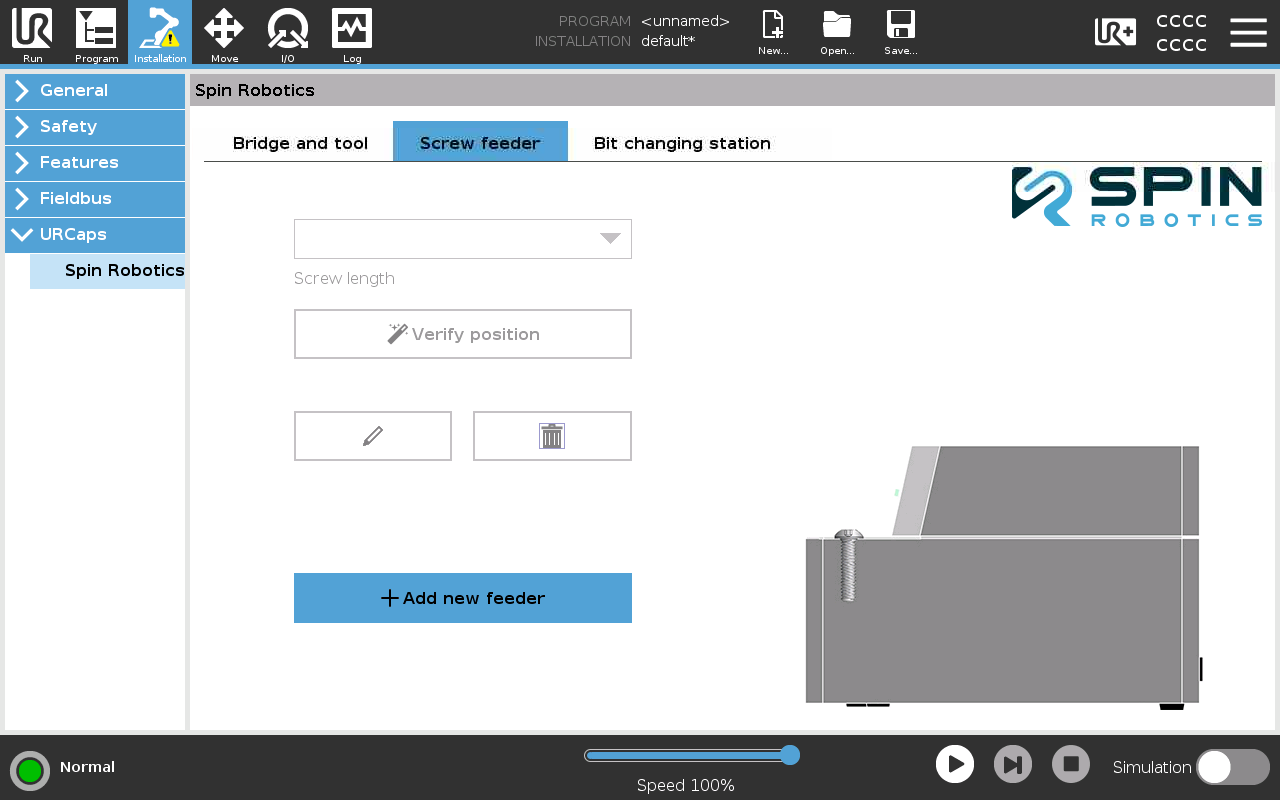

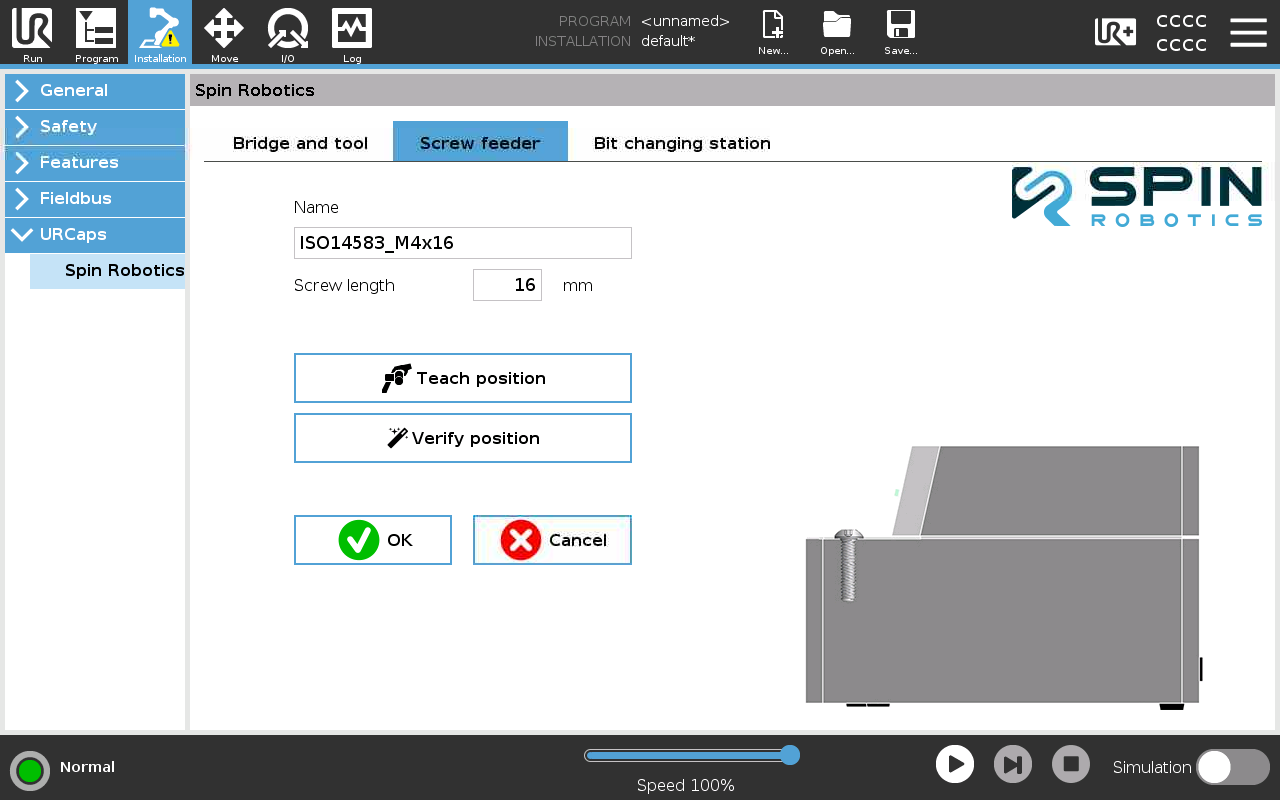

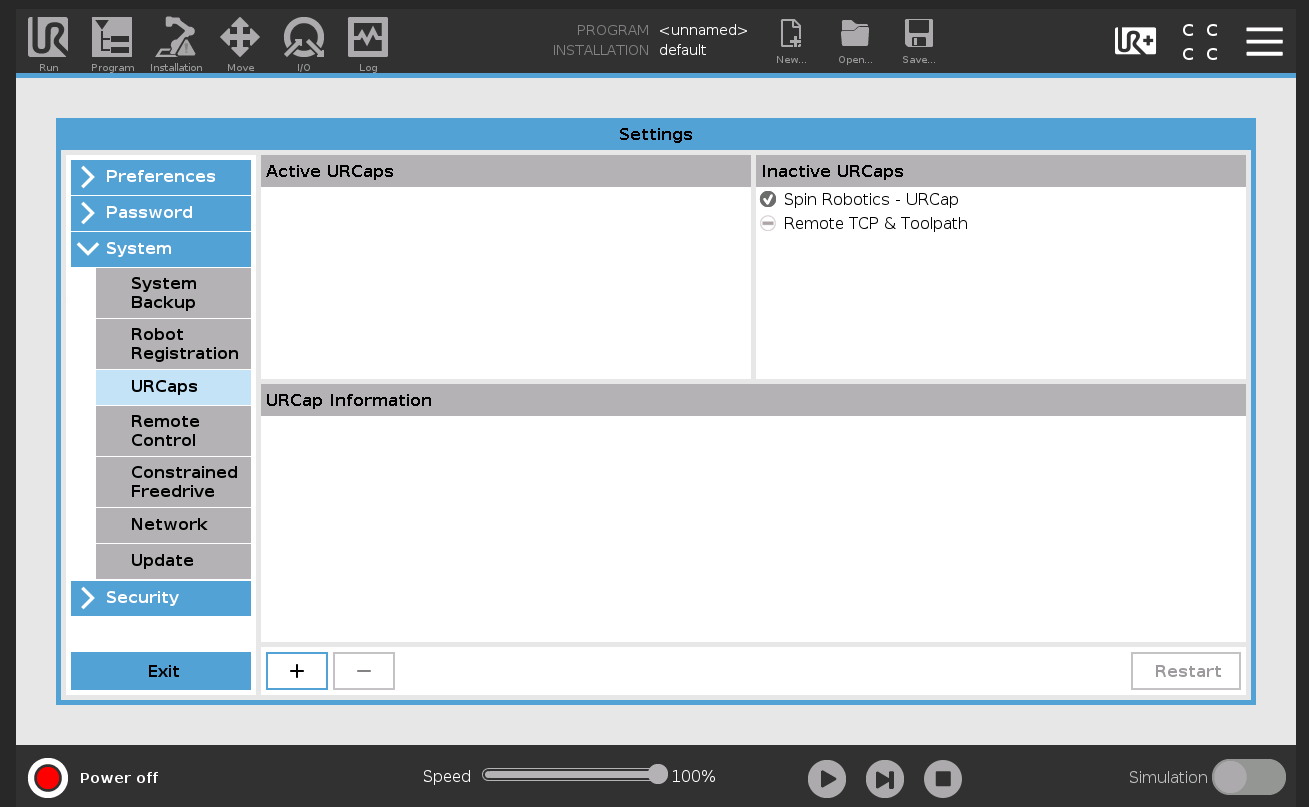

Insert the teach pen where the bit goes. Then, simply drag the robot using the freedrive function to the hole locations and save. It's that simple to program a screwdriving sequence with a Spin Robotics tool!Highly flexible

•

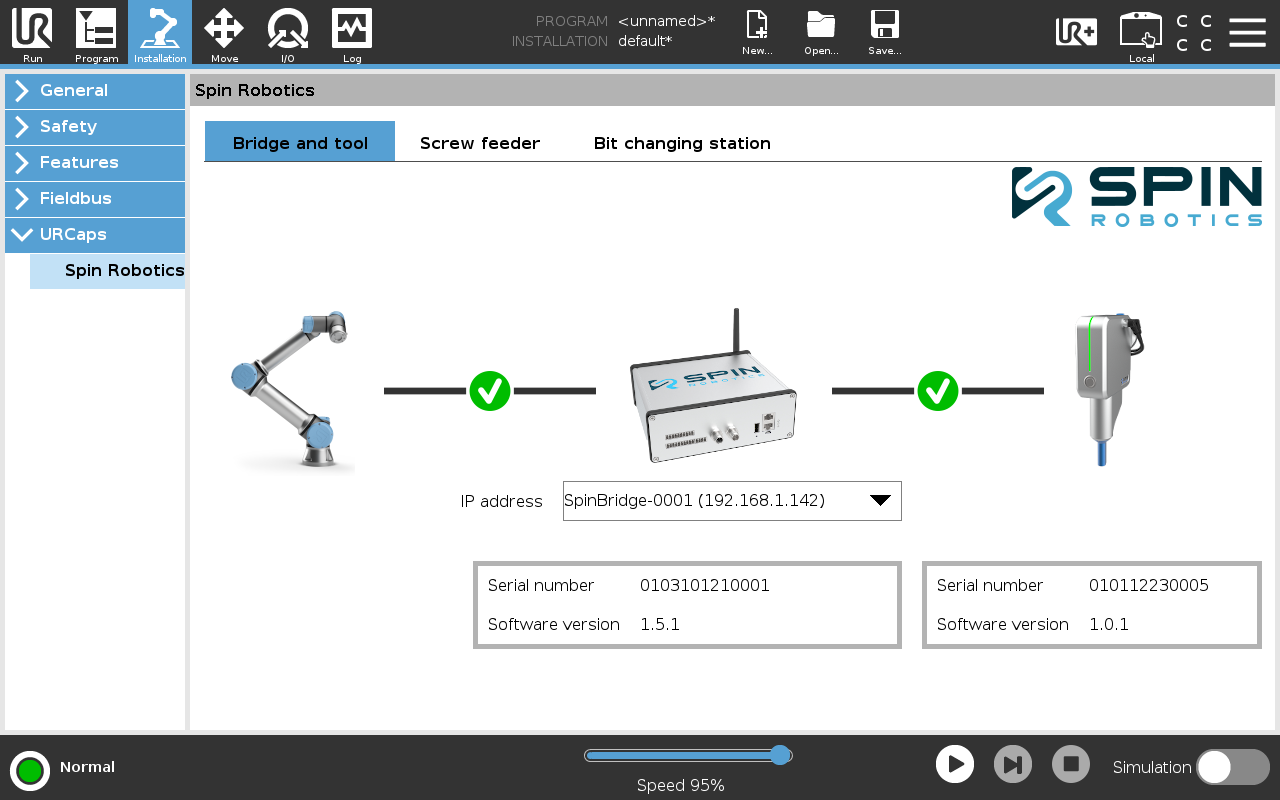

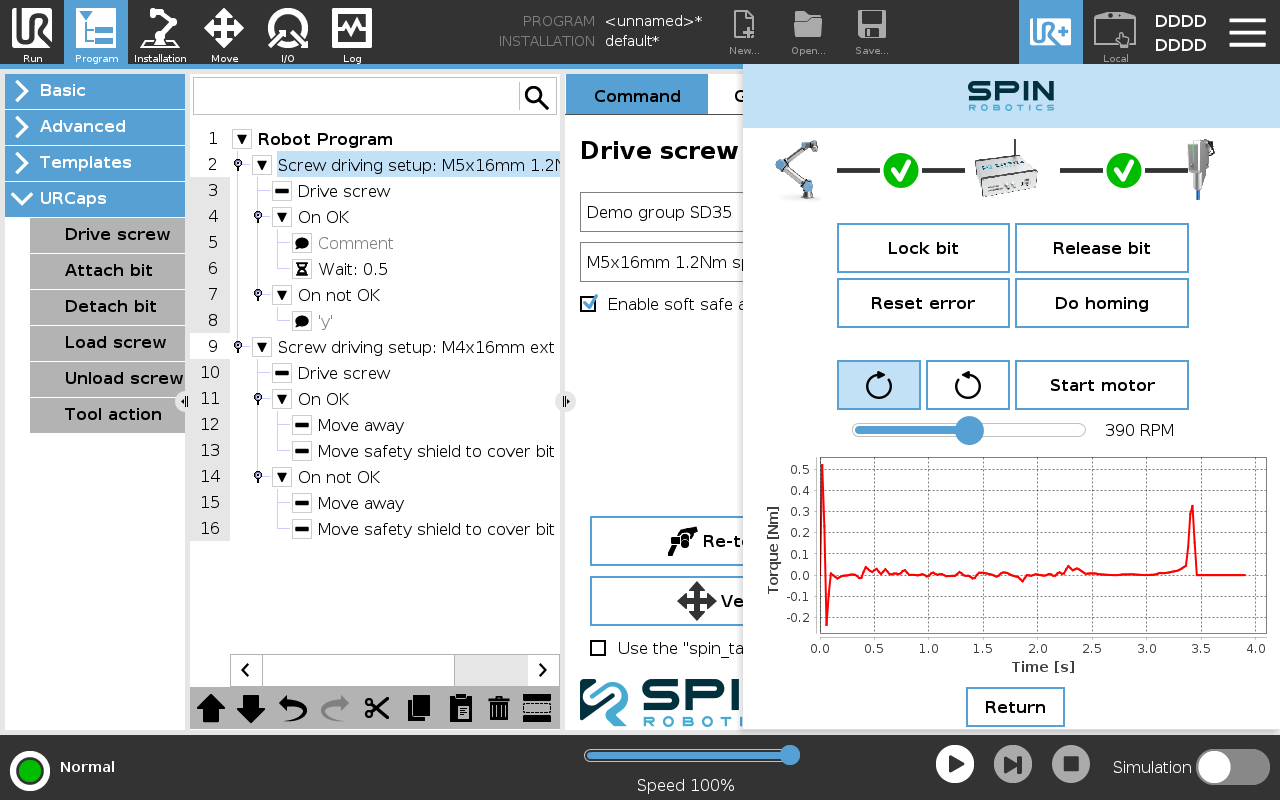

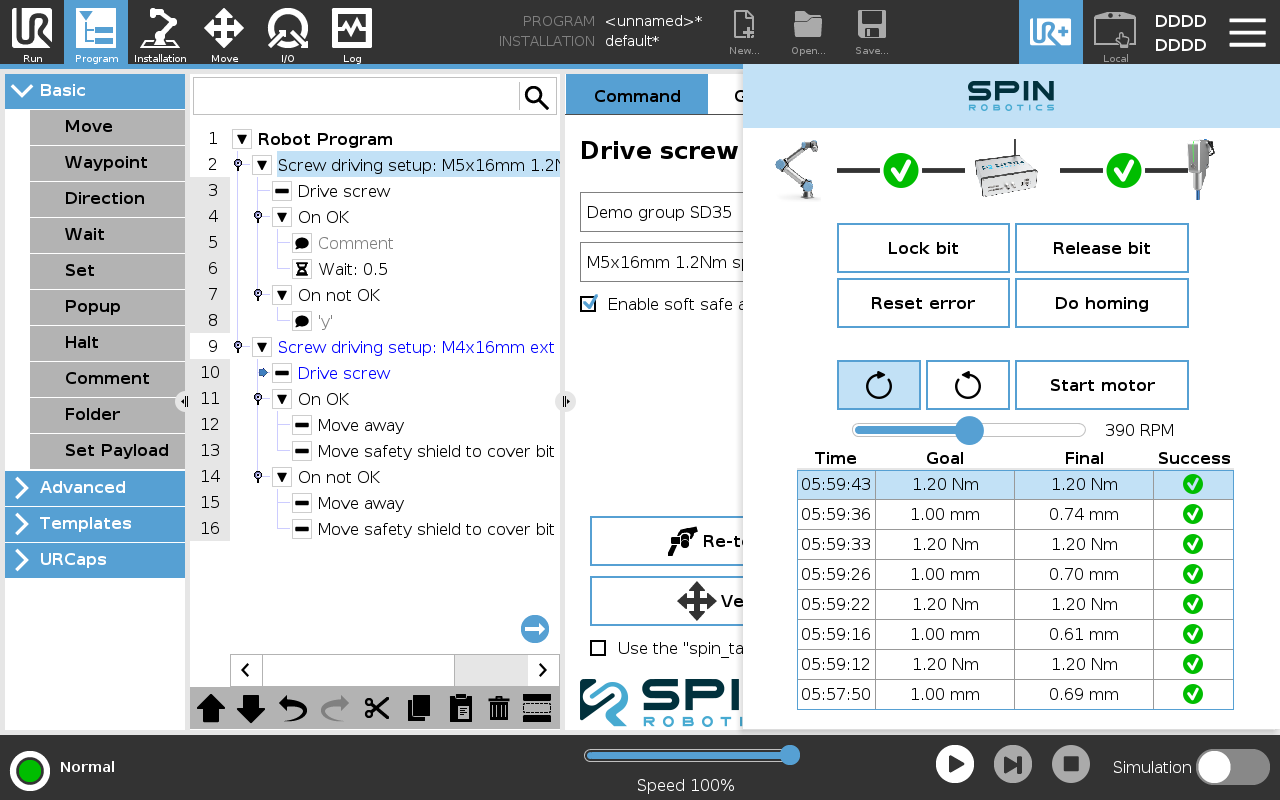

Once you have programmed a screwdriving sequence, it is stored and ready to use whenever needed. With the ability to store up to 300 different screwdriving sequences on the Spin Bridge, you are ensured the highest level of flexibility with Spin Robotics.Retrieve your screw-insertion data

•

The Spin-Bridge gathers past and real-time data from your screw insertions. Via OPC-UA you have the ability to extract this data into your ERP system as needed.Tech Support

•

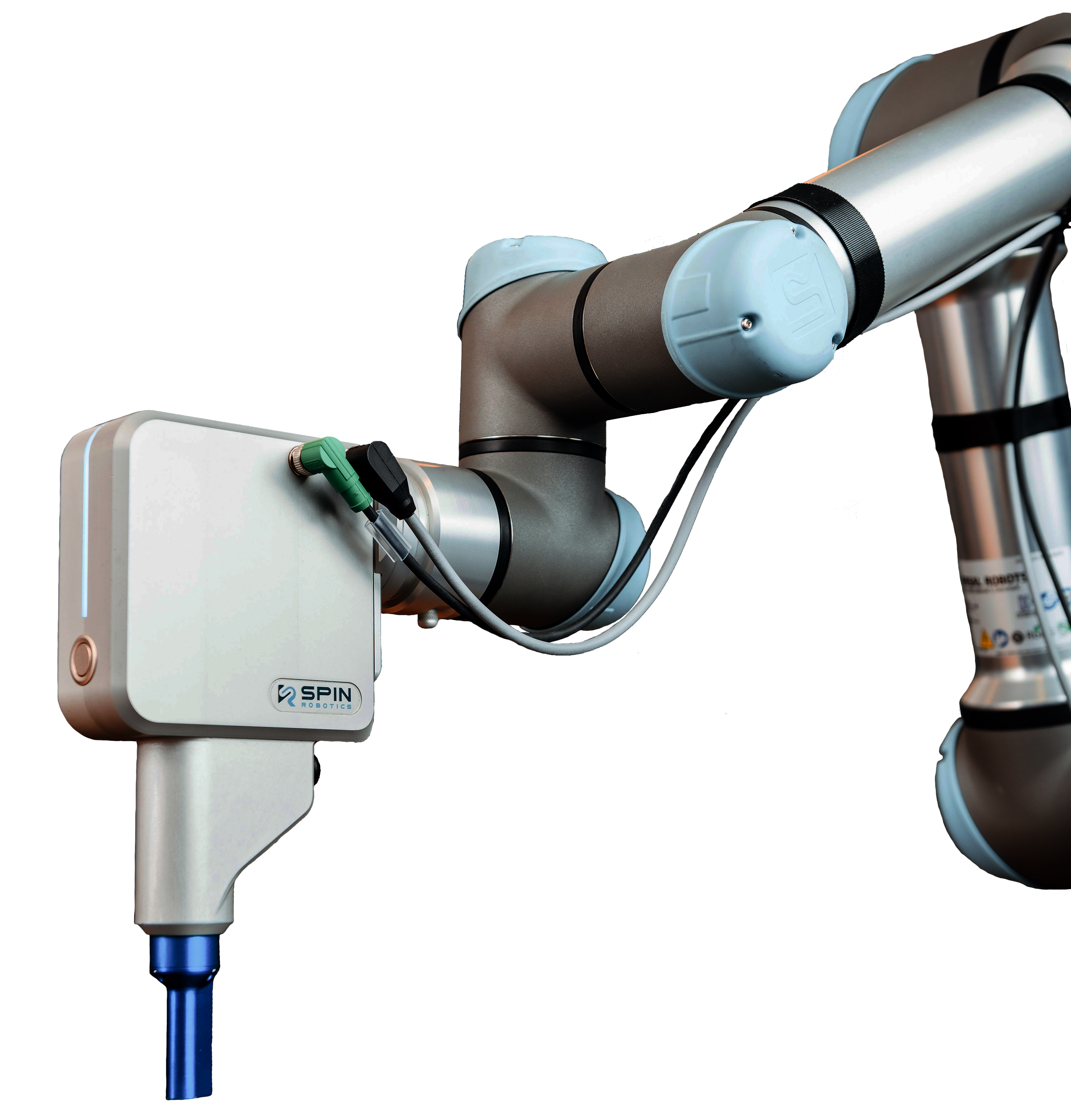

Your success is important to us! That's why we are ready to help, if you ever have any problems with a Spin Robotics product.SD-Series End-of-arm tooling

Key Benefits

01

Truly Collaborative

We connect humans and cobots through seamless integration of robots and screwdriving applications, all while ensuring safety is not compromised.

02

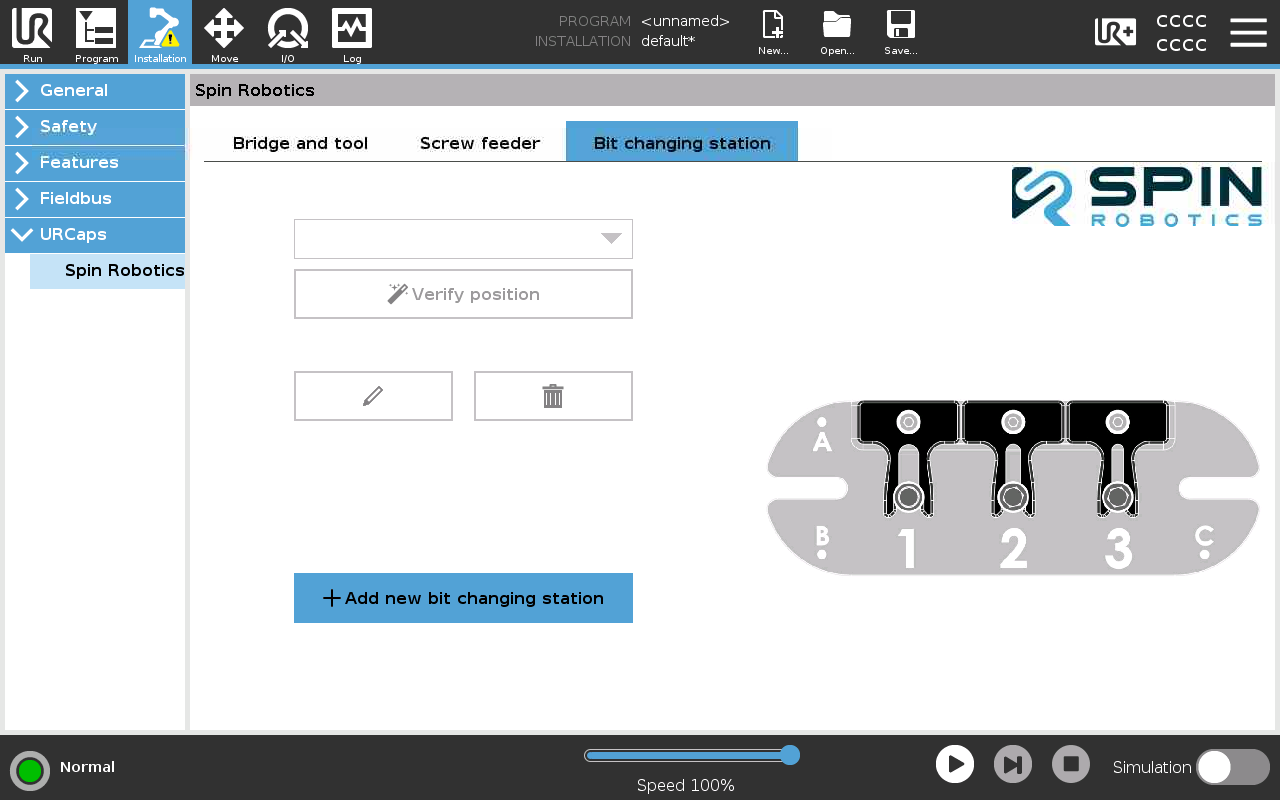

Automatic bit changer

With the ability to change bits faster than an individual manual exchange, the automatic bit changer increases flexibility and productivity, allowing you to insert up to six screws in under a minute.

03

Slim Design

Our Slim Design allows our solution to reach narrow spaces with a torque range of 0.4 – 12.0 Nm. This makes it easier to operate in confined areas without compromising performance.

04

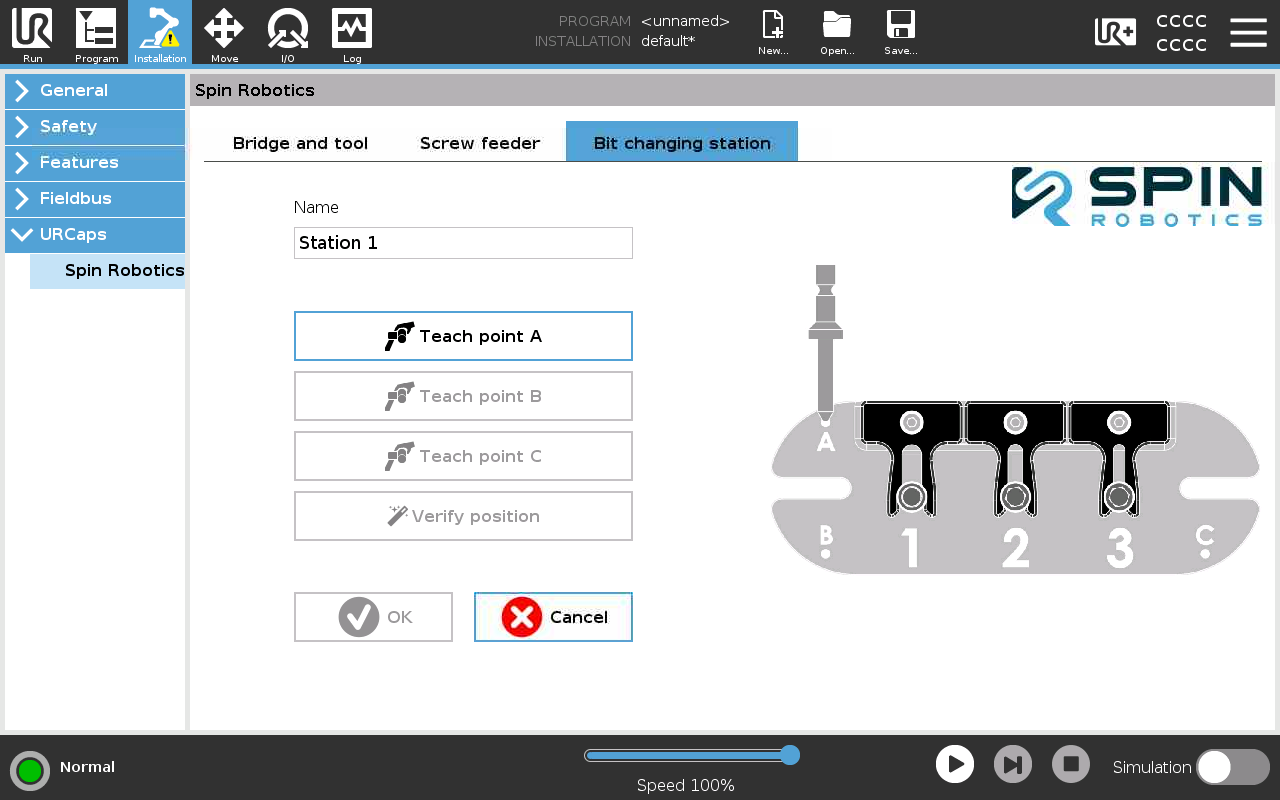

Easy Robot programming

The SD-series is fast to deploy in your production. Insert the teach pointer and simply drag the robot to each screw location. You will be up and running in no time!

Key Benefits

Truly Collaborative

We connect humans and cobots through seamless integration of robots and screwdriving applications, all while ensuring safety is not compromised.

SD-Series download

There are no files or folders yet.

Become a partner

Are you interested in the Spin Robotics products? Learn more about the advantages of adding our products to your portfolio – for both you and your customers.

Show allSpin Robotics across industries

Our tools have been successfully used across all these industries.

Automotive

Small Electronics

Industrial Electronics

Home Appliances

Show more

Ready to say goodbye to returned orders from customers?

Get a Quote

Need more info? Just Book a Live Demo.

Are you interested in the return of your investment?

Every investment needs to provide a solid return. Calculate your return on investment on the collaborative screwdriver products with our simple ROI calculator.

Get startedWithout any obligation to provide your e-mail adress.