Spin Bridge

The Spin Bridge is the all-in-one screwdriving process controller. Setup your screw programs easily at the Spin Dashboard and check the results from each screw. The integrated OPC-UA server makes result management easy.

- Connecting tool and robot controller

- OPC-UA* Server for easy ERP & MES integration

- Sophisticated result management

- Included in all Spin Robotics application kits

Get a Quote

Download Product SheetScrewdriving process controller for all Spin Robotics screwdrivers

The Spin Bridge monitors and controls the actual screwdriving process – it ensures that the preset speed, torque and depth are being maintained.

Complex screwdriving applications

•

The Spin Bridge is evaluating the screw process and document all screwdriving data.Easy configuration of screw programs

•

With the SpinDashboard you easily setup and configure your screw programs.Visualization on any PC, tablet or smartphone

•

Results from the screwdriving process can be visualized on any PC, tablet or smartphone with a webbrowser.Spin Bridge screw process controller

Key Benefits

01

Screwdriving process with flexible step programming

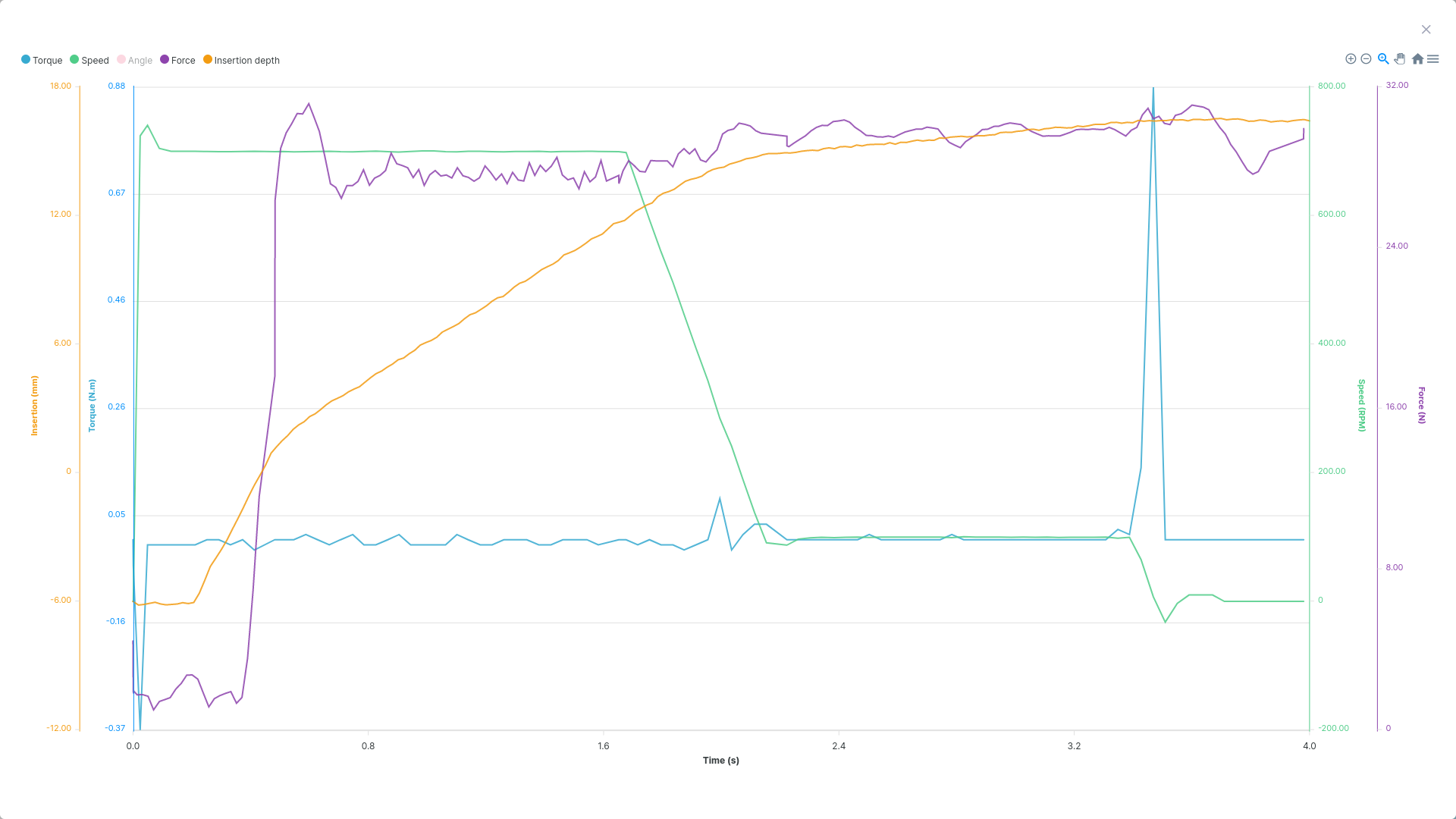

Detailed information about the screwdriving curves and characteristics can be output via SpinDashboard or OPC-UA.

02

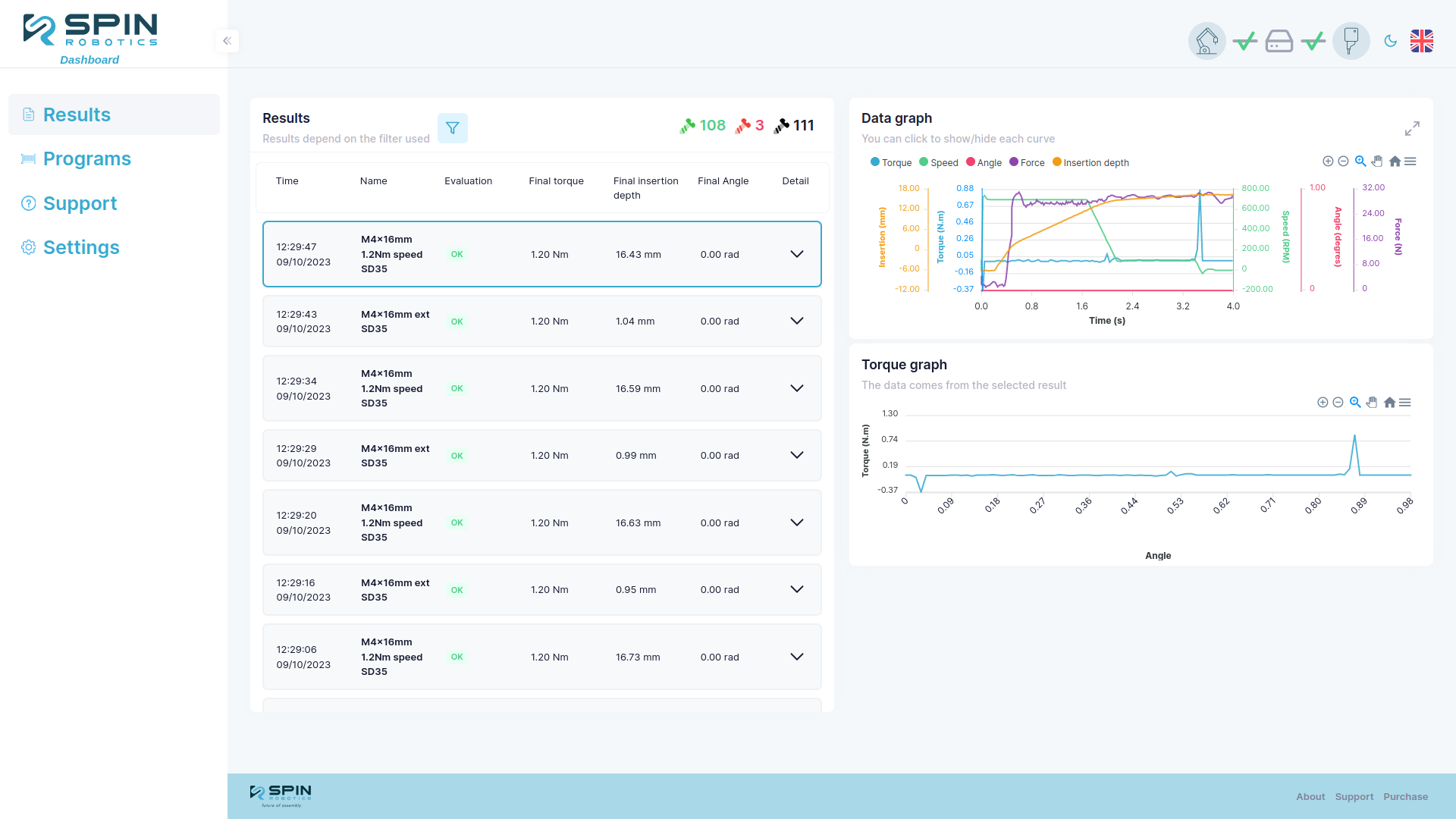

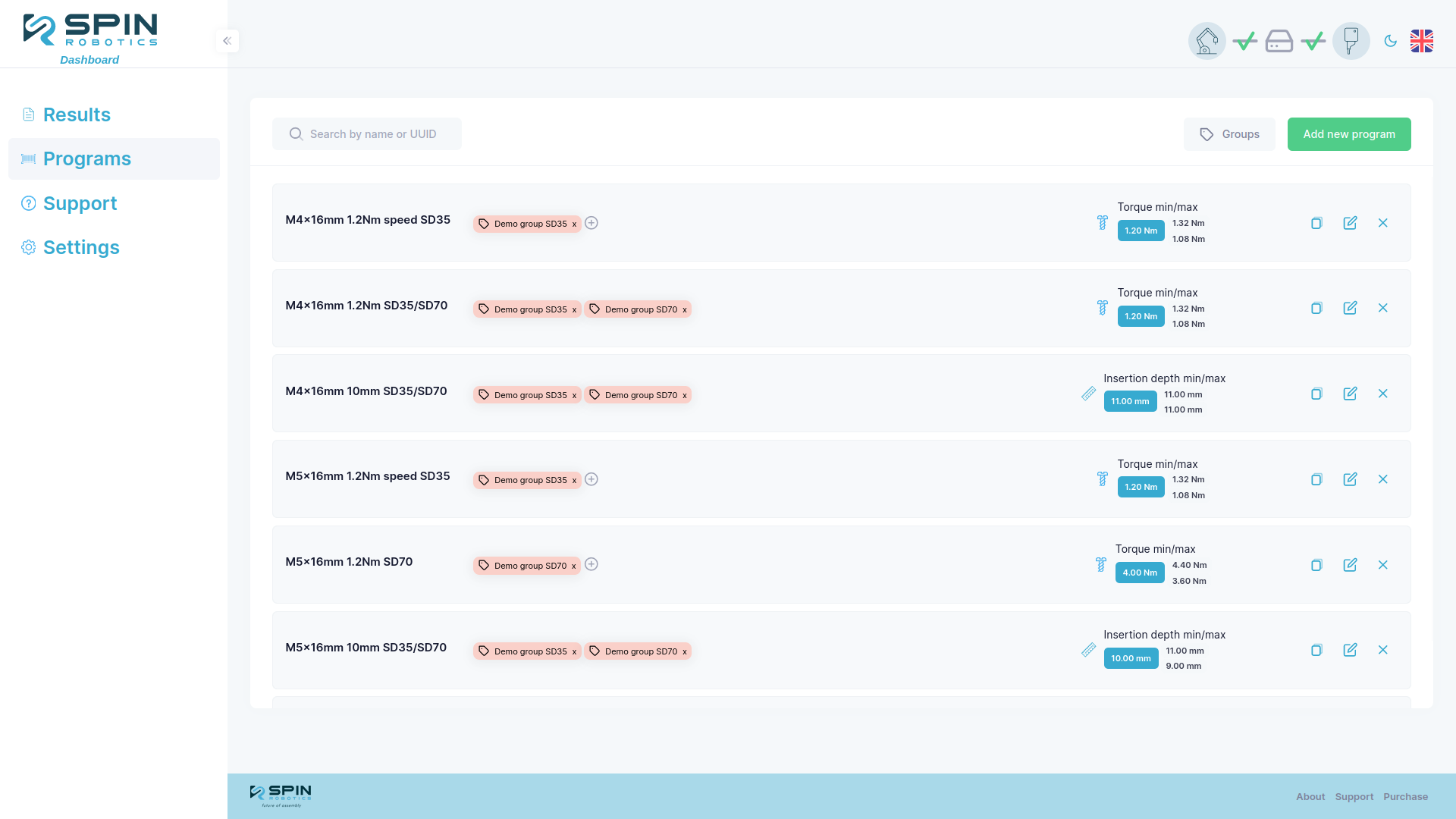

Detailed result management

Process evaluation and documentation of screwdriving/result data through the SpinDashboard software

03

Compatible with all Spin Robotics screwdrivers

The Spin Bridge screw process controller are compatible with all end-of-arm tool from Spin Robotics. The Spin Bridge assures seamless integration between the robot and screwdriver tool.

04

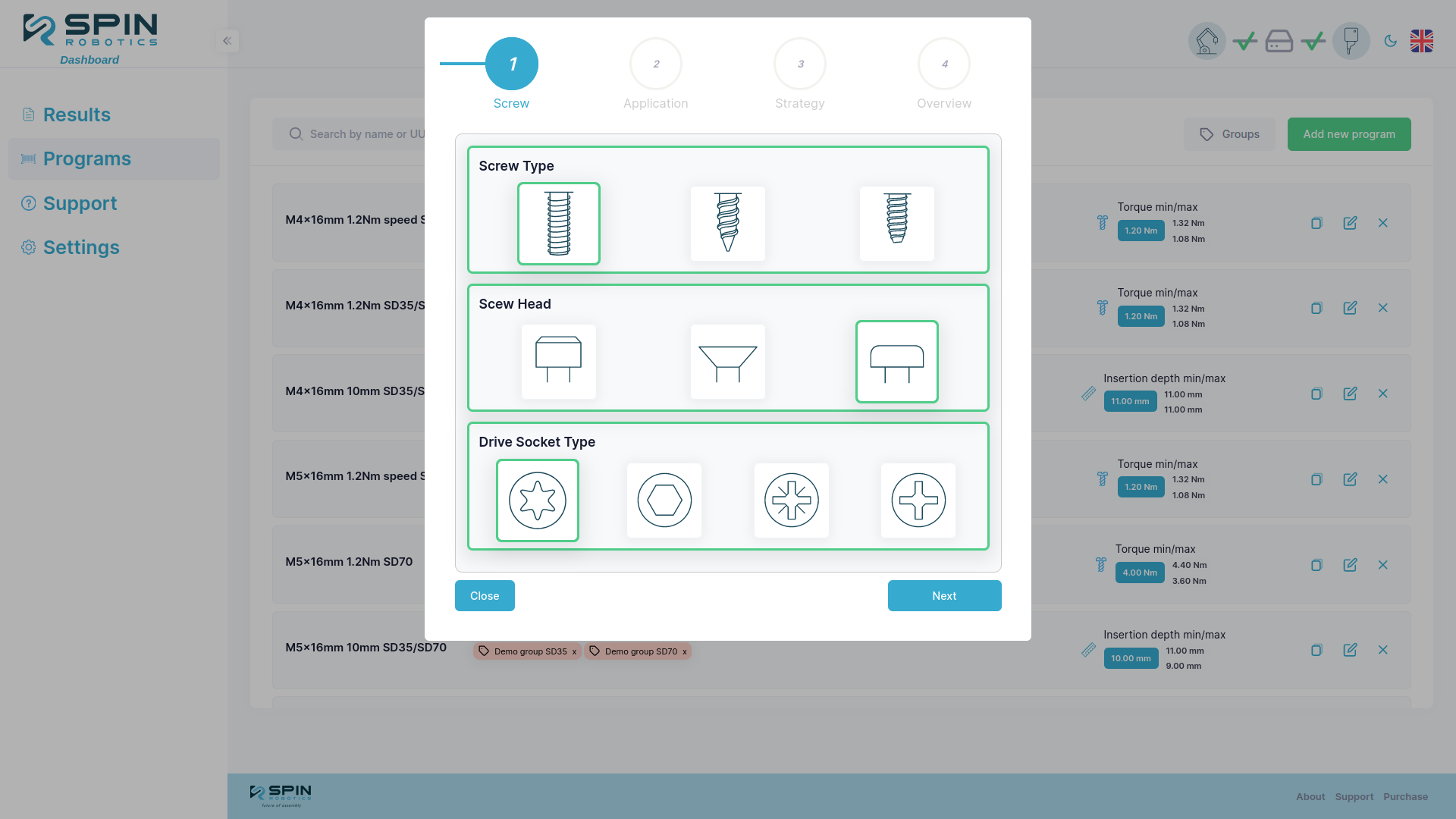

Easy programming of complex screwdriving tasks

Complex screwdriving tasks with simple parameterization using the intuitive step based wizard.

Key Benefits

Screwdriving process with flexible step programming

Detailed information about the screwdriving curves and characteristics can be output via SpinDashboard or OPC-UA.

Become a partner

Are you interested in the Spin Robotics products? Learn more about the advantages of adding our products to your portfolio – for both you and your customers.

Show allSpin Robotics across industries

Our tools have been successfully used across all these industries.

Automotive

Small Electronics

Industrial Electronics

Home Appliances

Show more

Ready to say goodbye to returned orders from customers?

Get a Quote

Need more info? Just Book a Live Demo.

Are you interested in the return of your investment?

Every investment needs to provide a solid return. Calculate your return on investment on the collaborative screwdriver products with our simple ROI calculator.

Get startedWithout any obligation to provide your e-mail adress.