Traceability and Optimization powered by OPC UA

What is OPC UA?

OPC UA (Open Platform Communications Unified Architecture) is a machine-to-machine communication standard for industrial automation developed by the OPC Foundation. It is designed to be platform-independent and provides a secure and reliable way to exchange data between devices and systems in a manufacturing environment. OPC UA supports a wide range of data types and information models, making it suitable for various applications, from simple sensor data to complex manufacturing processes connected in your network.

Benefits of using OPC UA

Interoperability: OPC UA enables seamless communication between different devices and systems, regardless of the manufacturer. This is particularly important in a diverse manufacturing environment where multiple systems need to work together.

Scalability: The platform-independent nature of OPC UA allows manufacturers to easily scale their systems by adding new devices and applications without worrying about compatibility issues.

Security: OPC UA includes built-in security features such as encryption, authentication, and access control, ensuring that sensitive data is protected during transmission.

Data Modeling: OPC UA supports complex data models, allowing manufacturers to represent their processes and equipment in a way that is both human-readable and machine-readable.

Future-Proofing: By adopting OPC UA, manufacturers can ensure that their systems are compatible with future advancements in technology and industry standards.

Spin Robotics and OPC UA

As a proponent of open standards, Spin Robotics embraces OPC UA as a key technology. This includes the OPC UA Companion Specification OPC 40451-1: Tightening Systems. This Companion Specification describes an interoperable interface of joining systems and components. Use cases are asset management, condition monitoring, and representation of joining results. The specification is authored by Industrial Joining Technologies (IJT), a work group under the VDMA Integrated Assembly Solutions department. Spin Robotics is a member of VDMA.

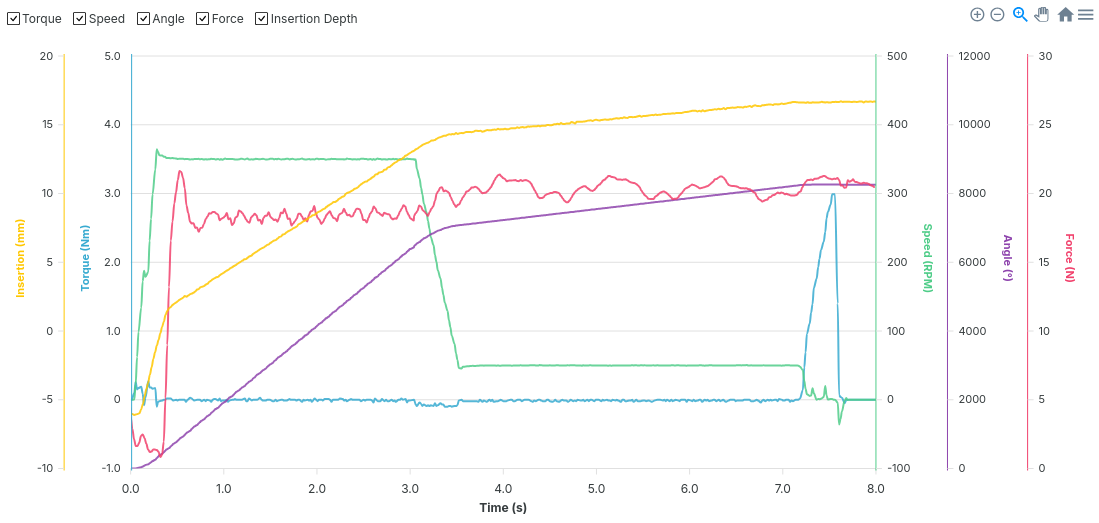

The most important implemented feature is Result Management. This feature enables comprehensive collection, storage, and analysis of joining results. Manufacturers can monitor key process parameters such as torque, angle, robot position, and timestamp, supporting process optimization and traceability.

Main figurr: OPC UA Result data includes data traces of torque, angle, tool speed, and other key parameters.

Another feature is Asset Management: It facilitates efficient management and monitoring of assets, including SpinBridge controllers and SD Series tools. This ensures up-to-date asset information, status tracking, and streamlined maintenance.

Integration with your systems

Thanks to the OPC UA compatibility, the Spin Robotics platform allows for data exchange between different devices and applications, including PLCs (Programmable Logic Controllers) and information systems like ERP and MES.

Here are some ERP (Enterprise Resource Planning), MOM (Manufacturing Operations Management) and MES (Manufacturing Execution Systems) platforms known to support OPC UA integration:

- SAP ERP (with Plant Connectivity and MII)

- Microsoft Dynamics 365 (with OPC UA connectors)

- Oracle NetSuite (via integration middleware)

- Infor CloudSuite Industrial (SyteLine)

- IFS Applications

- Epicor ERP

- Siemens Opcenter Execution (formerly SIMATIC IT)

- Rockwell Automation FactoryTalk ProductionCentre

- GE Digital Proficy MES

- AVEVA Manufacturing Execution System (formerly Wonderware MES)

- ABB Ability Manufacturing Operations Management

- Tulip

- Honeywell Manufacturing Execution System

- MPDV HYDRA MES

- iTAC.MES.Suite

- Critical Manufacturing MES

- Fujitsu COLMINA

Note: Always verify OPC UA support and version compatibility with the vendor, as features may change over time.