Benchmark Electronics - Enhance quality, repeatability & traceability with cobot assembly

Standardize screwdriving with fast deployment, consistent torque control, and full process visibility.

About the Company

Benchmark Electronics is a global provider of engineering, design, and manufacturing services with a strong focus on innovation and quality. The company partners with industry leaders to bring advanced technology solutions to market, supporting customers in sectors such as medical devices, industrial automation, aerospace, and electronics. With a commitment to precision and reliability, Benchmark delivers world-class production capabilities and end-to-end support, enabling businesses to accelerate development and scale manufacturing efficiently.

The Challenge

Benchmark Electronics needed to streamline their assembly process to keep up with rising production demands and strict quality standards. Manual screwdriving was slowing down throughput and creating risks of inconsistency, while operators were tied up with repetitive, low-value tasks. To maintain competitiveness and ensure reliable fastening, Benchmark required an automation solution that could be easily integrated into their existing production setup and deliver consistent, measurable performance.

The Solution

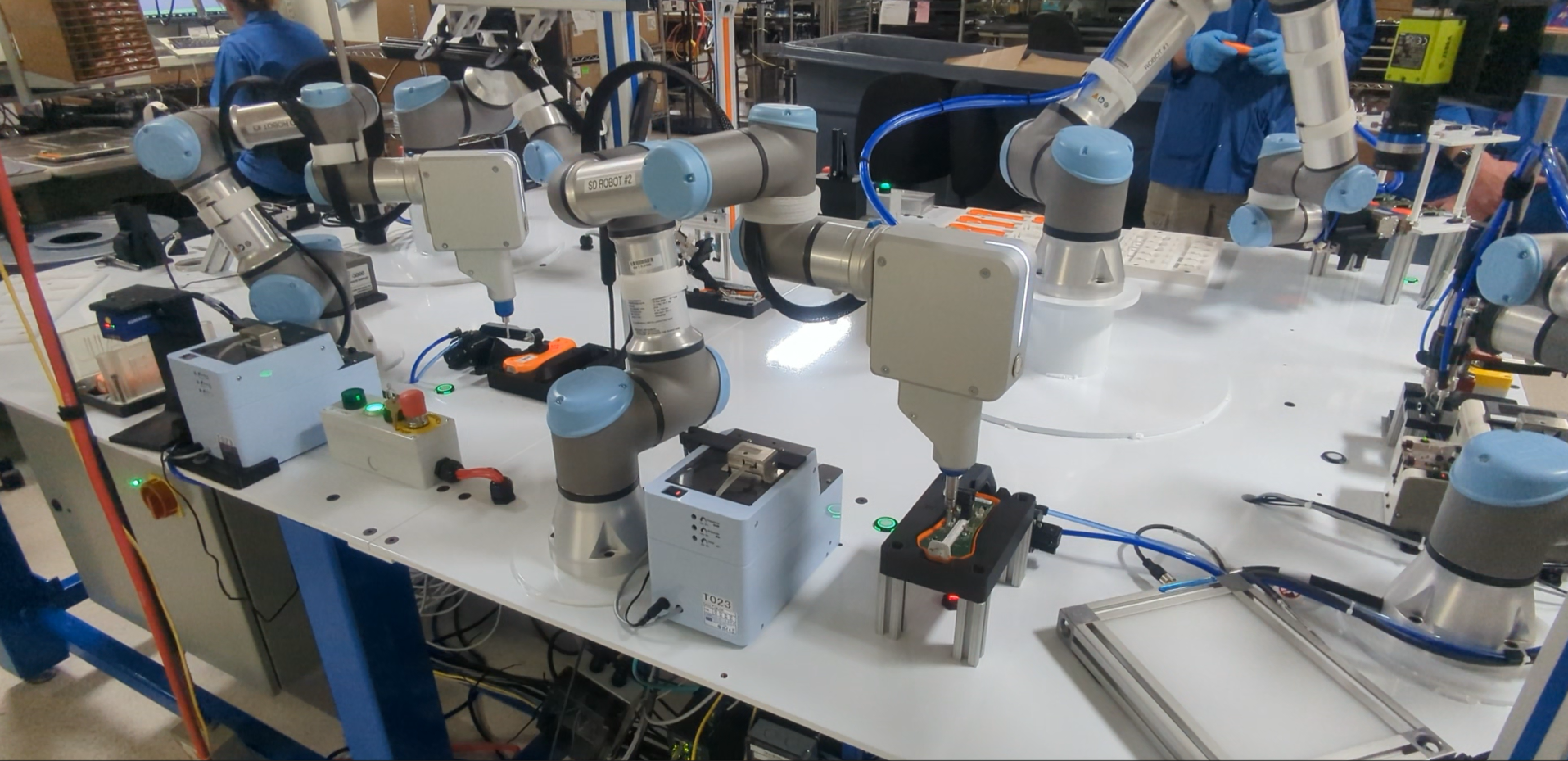

To meet their production goals, Benchmark Electronics integrated Spin Robotics’ SD-Series collaborative screwdrivers together with the SpinBridge and screw feeding systems. The SD tools delivered consistent torque accuracy and reliability, automating the repetitive screwdriving tasks that previously slowed down production. With SpinBridge providing real-time process data and torque monitoring, Benchmark gained greater control and insight into their assembly operations. The solution proved easy to integrate into existing lines, enabling Benchmark to increase efficiency, reduce manual strain, and maintain the high-quality standards their customers depend on.

Play video

"We have two of them, and so far we are very happy"

Nigel Smith

Automation Engineer

Challenges Solved

Manual screwdriving slowed down throughput and limited efficiency

Risk of inconsistent fastening quality in production

Operators tied up with repetitive, low-value tasks

Requirement to maintain strict quality standards while scaling production

Key Value Drivers

Consistent torque accuracy and reliable screwdriving

Increased assembly efficiency and reduced cycle times

Real-time process data and torque monitoring via SpinBridge

Operators freed from repetitive tasks to focus on higher-value work

Ready to increase profit margins and production quality?

Get a Quote

Need more info? Just Book a Live Demo.

Are you interested in the return of your investment?

Every investment needs to provide a solid return. Calculate your return on investment on the collaborative screwdriver products with our simple ROI calculator.

Get startedWithout any obligation to provide your e-mail adress.