High Precision Torque Tightening Systems: Reduce Errors and Boost Productivity with Automation

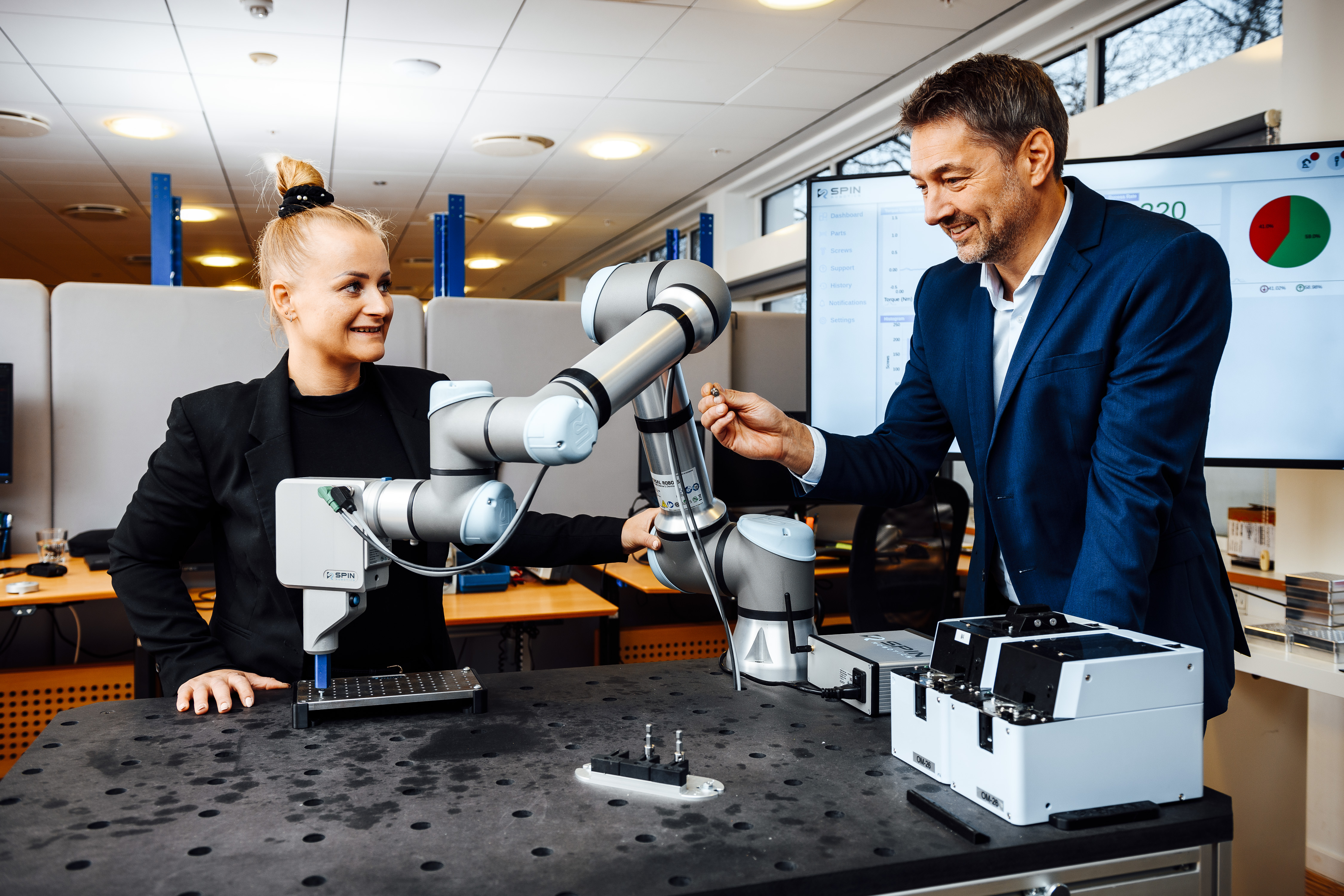

Spin Robotics delivers tightening systems that transform manufacturing operations. Companies face growing pressure to increase output while maintaining quality and protecting workers. Our high-precision torque tightening systems directly address these challenges.

We understand that manufacturers need reliable solutions that make financial sense. Our automated systems cut down on errors, speed up production, and create safer working conditions. The results speak for themselves - customers report up to 30% faster assembly times and 95% fewer quality issues after implementing our technology.

Our solutions combine advanced robotics with user-friendly controls, making automation accessible for businesses of all sizes. Whether you're dealing with complex assembly tasks or repetitive tightening operations, our systems adapt to your needs while providing consistent, measurable results.

The benefits extend beyond just numbers. Workers experience less physical strain, quality teams gain better data tracking, and production managers see smoother operations. This approach helps companies achieve their goals while taking care of their most valuable asset - their people.

How our high-precision torque tightening system can boost your productivity and operations

Immediate Cost Advantages

Spin Robotics solutions deliver significant financial benefits right from the start. Our automated torque tightening systems cost 40% less than traditional automation equipment, making them accessible for companies of all sizes.

Installation takes just 2-3 hours, cutting setup expenses dramatically. Most customers see their investment returned within 12-18 months through improved efficiency and reduced errors. One manufacturing client saved $45,000 in the first year after switching to our system.

The energy-smart design of our solutions means lower power bills too. Our systems use 30% less electricity than standard automated tools. A recent case study showed annual energy savings of $3,800 for a medium-sized production line.

We also reduce hidden costs:

- No special training needed

- Minimal maintenance requirements

- Lower insurance premiums due to enhanced safety

- Fewer quality control issues and product returns

The numbers tell the story - an automotive company cut their monthly operating costs $2,500 after implementing our torque system. Their error rate dropped from 3% to 0.1%, nearly eliminating costly rework.

Our flexible payment options and leasing programs make getting started even easier. We help customers choose the most cost-effective solution for their specific needs.

Operational Efficiency Gains

Spin Robotics solutions deliver clear efficiency improvements from day one. Our automated torque tightening systems cut setup time to just minutes, letting production lines keep moving with minimal interruption.

Customers report 40% faster assembly times after implementing our solutions. The precision control means tasks get done right the first time, reducing costly rework and quality issues. Our systems maintain consistent torque levels across thousands of repetitions, something that's impossible to achieve manually.

The flexible programming allows quick changes between different products or specifications. Workers can switch between tasks in under 5 minutes without complex reprogramming. This flexibility helps manufacturing teams adapt to changing demands while maintaining high output.

Real customer data shows:

- 99.9% accuracy in torque application

- 37% reduction in assembly errors

- 30% increase in daily production output

- Zero quality rejections due to incorrect torque

The built-in monitoring captures detailed data about each operation. This helps teams spot trends, optimize processes, and prove compliance - all automatically. Managers get clear insights without extra work.

These efficiency gains add up to significant productivity improvements. One automotive customer increased their output from 200 to 260 units per shift while reducing quality issues to near-zero.

Workforce Enhancement

Spin Robotics solutions create healthier, more engaging workplaces for employees. Our automated systems take over repetitive tightening tasks, which reduces physical strain and prevents injuries from constant twisting motions.

Workers gain valuable skills through training on our user-friendly systems. Instead of performing manual tightening all day, they learn to operate and monitor advanced automation equipment. This knowledge helps them grow their careers while adding more value to your operations.

Our solutions free up your team to focus on complex tasks that need human judgment and creativity. The automated systems handle the repetitive work, letting employees use their skills for quality control, process improvement, and problem-solving.

Safety improves dramatically with our automated tightening systems. The precise torque control eliminates risks from over-tightening or inconsistent force application. Workers stay protected from strain injuries since they're no longer doing constant manual tightening motions.

Key workforce benefits include:

- Less physical strain and fewer repetitive motion injuries

- New technical skills through system operation

- More time for valuable strategic work

- Enhanced workplace safety standards

With Spin Robotics, you create an environment where employees can work smarter, safer, and more efficiently while developing new capabilities that benefit both them and your business.

Technical Advantages

Spin Robotics' torque tightening systems offer clear technical benefits that make automation simple and effective. The systems connect smoothly with your current equipment, requiring minimal changes to your setup.

The user-friendly programming interface lets operators make adjustments without special training. Workers can program new tightening sequences in minutes using the intuitive touch screen display. This means less time spent on complex programming and more time on productive work.

Our systems adapt easily to handle different tasks. Whether you need precise torque control for small electronics or powerful tightening for heavy machinery, the equipment adjusts automatically to meet your needs. The built-in sensors ensure exact torque every time, eliminating guesswork and reducing errors.

Looking ahead, these systems are designed to grow with your business. Regular software updates add new features and capabilities, protecting your investment. The modular design allows you to add components as your needs change, without replacing entire systems.

Key technical features include:

- Plug-and-play connectivity

- Simple touch screen controls

- Automatic torque adjustment

- Real-time error detection

- Modular expansion options

These technical advantages help you achieve consistent quality while keeping operations simple and efficient.

Long-term Business Benefits

Spin Robotics solutions deliver lasting advantages that strengthen your business position. Our automated torque tightening systems help you stay ahead of competitors through consistent quality and reliable performance.

Quality improvements show up directly in your metrics. Customers report up to 99.9% accuracy in torque applications, leading to fewer defects and returns. This precision creates satisfied customers who keep coming back.

The system grows with your needs. You can start with a single unit and add more as demand increases. This scalable approach lets you manage costs while expanding production capacity.

Our solutions also help you respond quickly to market changes. The easy-to-program interface means you can adjust torque settings and switch between different programs for screw insertion into different products in minutes instead of hours.

Real results from manufacturing clients show:

- 40% reduction in quality-related issues

- 60% faster product changeovers

- 30% increase in production output

These improvements create a strong foundation for sustainable growth. As your business expands, our automated systems maintain consistent quality while handling higher volumes.

The data tracking features give you clear insights into production trends. This helps you make smart decisions about scaling operations and meeting customer needs.

Conclusion

Spin Robotics torque tightening systems deliver clear, measurable advantages for manufacturing operations. These solutions cut down errors, boost output, and create safer workspaces for employees. The combination of precise torque control, reliable data tracking, and user-friendly operation makes these systems a smart investment for companies looking to strengthen their production capabilities.

Our customers consistently report significant improvements:

- Up to 95% reduction in assembly errors

- 40% increase in production speed

- 60% decrease in worker strain-related issues

- 30% lower maintenance costs

The path forward is clear. Spin Robotics systems offer a practical way to modernize assembly operations while putting worker wellbeing first. We stand ready to help you transform your production floor into a more efficient, safer, and more productive environment.

Ready to enhance your operations? Contact our team to schedule a demonstration and see these benefits firsthand.