Areera - Intelligent Automation for Smarter Screen Recycling

Areera boosts efficiency and consistency with a fully integrated robotic cell powered by Spin Robotics’ SD35 screwdrivers

About the Company

Areera – Intelligent Screen Recycling is a UK leader in sustainable technology recycling. In 2021, they joined forces with The Buy It Direct Group to design and build Europe’s most technologically advanced screen-based recycling facility, located in West Yorkshire. Partnering with councils, recyclers, manufacturers, and retailers, Areera processes up to 20 times more display equipment than traditional plants, meeting the prestigious WEEELABEX certification standards. As the first UK recycler certified for both flat panel displays and WEEE plastics, Areera sets new benchmarks for quality, efficiency, and environmental responsibility in electronics recycling.

The Challenge

Areera needed to optimize the dismantling of flat panel display equipment to meet the high demands of their advanced recycling facility. Manual screw removal was slowing down throughput and consuming valuable operator time. The process required precision and consistency across many different screen models, while also supporting Areera’s commitment to WEEELABEX-certified recycling standards. To scale operations efficiently, they required a robotic solution that could automate repetitive tasks, be adapted to different screen types, and integrate seamlessly into a complete recycling workflow.

The Solution

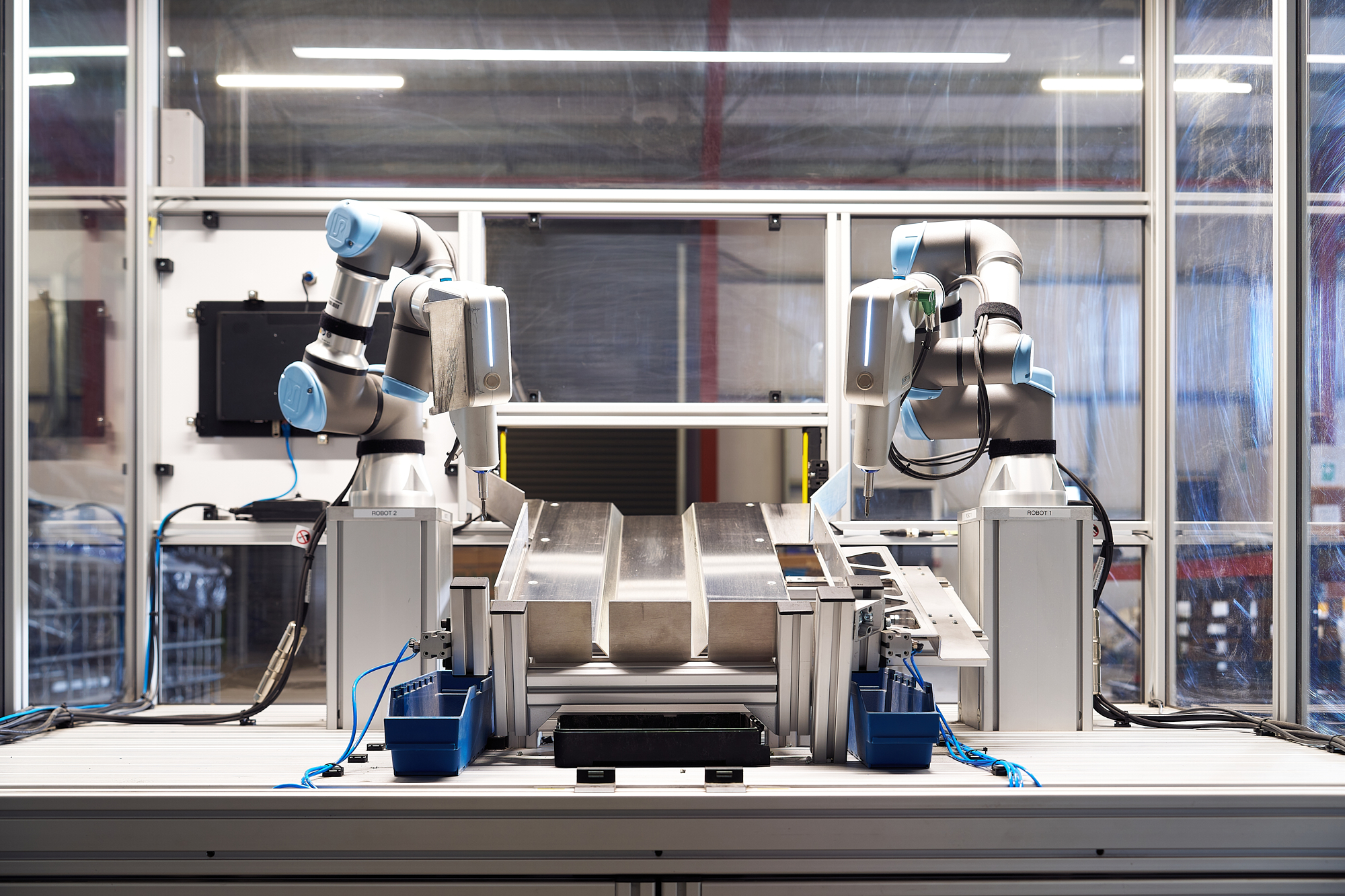

Spin Robotics designed, produced, and integrated a complete robotic cell for Areera’s facility. The setup features two UR3e cobots equipped with SD35 screwdrivers, programmed to handle a wide range of screen models. The process is simple and efficient: an operator places a screen in the cell, selects the correct model on the touchscreen, and starts the cycle. The robots automatically unscrew the back panel and eject the screen for operator handling. After the operator inserts the remaining part, the cell continues with the second unscrewing step before the operator completes the final disassembly. This semi-automated workflow ensures faster cycle times, consistent results, and reduced operator workload while maintaining maximum flexibility in handling different types of screens.

Play video

"The partnership of areera bringing an idea on using robotics to de-manufacture computer monitors to Spin Robotics has worked extremely well. From a proof of concept to a physical delivered working cell within 12 Months was some achievement. We are now actively working with Spin Robotics on new projects for 2026 and the coming years".

Craig Thompson

CEO

Challenges Solved

High volume of screen recycling required to meet growing demand

Need to reduce manual labor and repetitive screw removal tasks

Requirement for precise, consistent screwdriving across varied screen models

Integration of automation into a complete recycling cell

Key Value Drivers

Automated unscrewing of multiple screen types with SD35 cobot tools

Increased throughput compared to manual disassembly

Seamless operator–robot collaboration in a safe, efficient workflow

Easy handling with intuitive model selection and cycle control

Ready to increase profit margins and production quality?

Get a Quote

Need more info? Just Book a Live Demo.

Are you interested in the return of your investment?

Every investment needs to provide a solid return. Calculate your return on investment on the collaborative screwdriver products with our simple ROI calculator.

Get startedWithout any obligation to provide your e-mail adress.